OUR PRODUCTION LINES

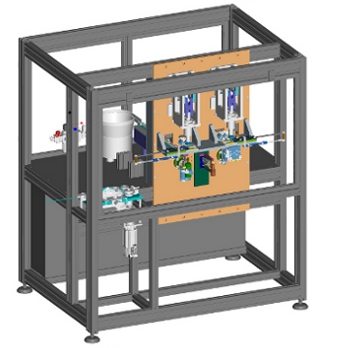

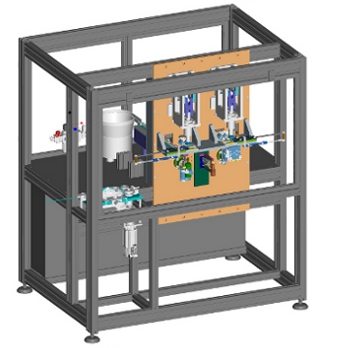

BOILER GROUP TEST BENCH

BOILER TEST BENCH

COFFEE GROUP TEST BENCH

VALVES GROUP TEST BENCH

DOSING MOTOR TEST BENCH

FILTER HOLDER TEST BENCH

VALVES TEST BENCH

BATH TEST BENCH

BOILER LIFE TEST BENCH

PLATE LIFE TEST BENCH

PUMP LIFE TEST BENCH

BUSHING MACHINE

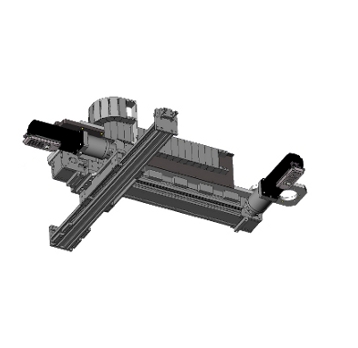

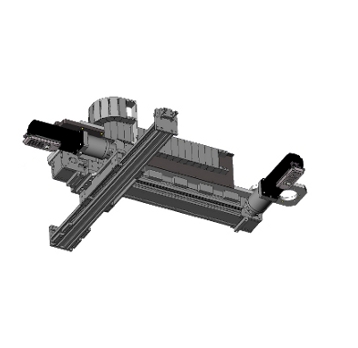

AXES