Production of components in composite material and carbon fiber.

Study, Design and Production of Components in Composite Material and Carbon Fiber, with compression molding technology (press printing) and use of structural adhesives.

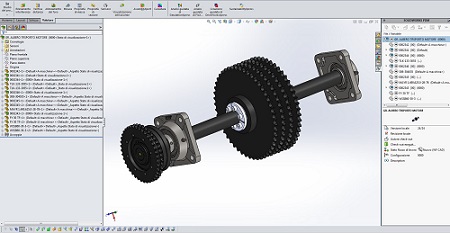

Mechanical studies and prototyping for special groups.

Design and dimensioning of mechanical units, realization of assembly studies, modeling and relative table settings.

Software: Solidworks®, PRO E® e Solide Edge®.

3D Printing Technology

Prototype development and test products or small production lots using 3D printing technology, thermoplastic materials, also loaded with glass fiber or continuous carbon thread.

Design and construction of electrical cabinets.

Design, sizing of components and construction of systems and control panels with related wiring diagrams.

Software: EPLAN 5/21/P8®, SPAC® e SABIK®.

SERVICES

What we offer

Rebuilding

Analysis of electronic and mechanical components on existing machines. Updates and revisions of machines or plants.

Traceability solution on production lines

The project stems from the common need for many customers to collect the fundamental data related to a product starting from its assembly to leaving the production line. The solution created is able to recover and persist the data of each individual product with a high degree of specificity making it possible to process and study such data over time. It is possible to keep track of the components used for the assembly of the product, the data and the results of the regulatory tests eventually carried out on it, the information regarding the production lot (quantity, codes, start date and so on), any defects found/resolved and it is possible to customize the system to retrieve additional key information. This data is automatically collected by the devices of the production line, thus ensuring a high degree of precision, and stored on a single support reliable and redundant where they are associated with a unique code together with the relative space-time references to allow a punctual interrogation of the production history. The technologies used include RFID, PLC, operator panels, OPC, high reliability PC Server, Microsoft .NET Framework and Microsoft SQL Server.

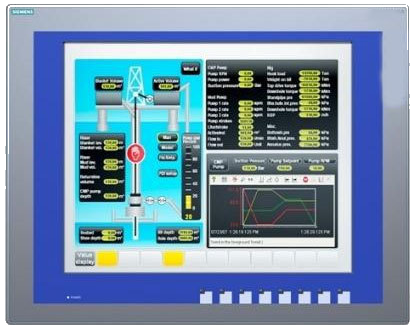

Errelle HMI project

Using the experience accumulated over years of interface implementation user in the automation field has developed a project to provide a unique, standardized and easily customizable support for the realization of these interfaces. The implemented system is in agreement with the MVC subdivision (Model View Controller) in order to group common functions into components, isolate its constituent parts and limit, regulate and therefore simplify their interactions. The architecture is of the client / server type, in which the server deals with the communication with the PLCs and with the client devices and with the persistence of the data to be displayed; while the clients take care of the presentation and interaction with the operators. The system offers a communication framework between client and server that includes several protocols and is open to the addition of additional data exchange methods. The technologies used include OPC, high-reliability PC server, PC / operator panels, Xml, Microsoft .NET Framework e Microsoft SQL Server.

Test Benches for testing and life testing of functional subgroups

During 2011, Errelle s.r.l. undertook research and development activities for the design and construction of different types of test benches.

In their construction, the prefixed objective is to test and test the life of functional sub-assemblies for household appliances in common use.

The tests studied can be summarized as follows:

- Tightness tests: ability to keep fluids under pressure or in free fall (air and water);

- Functional tests: they verify the correct assembly of the components and the correct intervention of the safety components in critical conditions;

- Flow checks: detection of obstructions or crushing of exposed pipes;

- Protective earth tests: verification of compliance with current regulations (D.Lgs 81/08, Ministerial Decree n. 37 of January, 22th 2008, norm CEI 64-8/4) to keep the masses at ground potential under normal use, providing protection by grounding;

- Checks on minimum and maximum current absorption in components subject to frequent start and stop cycles;

- The tests are assisted by automated stations whose task is to reduce the repetitive operations required of the skilled labor in the preparation and completion phases of the test cycle.

- The test benches are managed by dedicated software, written and compiled by Errelle S.r.l. to complete the test command phases and to analyze the results obtained.